Flöt grafskurðarvél, heitpressun, multiGRAFOTRONIC

350 200254G

Flöt grafskurðarvél, heitpressun, multi

GRAFOTRONIC

350 200254G

VB aukaskattur bætist við

67.500 EUR

Ástand

Notað

Staðsetning

Kruszyn Krajeński

Myndir sýna

Sýna kort

Upplýsingar um vélina

- Heiti vélar:

- Flöt grafskurðarvél, heitpressun, multi

- Framleiðandi:

- GRAFOTRONIC

- Gerð:

- 350 200254G

- Ástand:

- mjög gott (notað)

- Virkni:

- fullkomlega virkur

Verð og staðsetning

VB aukaskattur bætist við

67.500 EUR

- Staðsetning:

- Ceramiczna 15, 86-005 Białe Błota, PL

Hringdu

Tilboðsupplýsingar

- Auglýsingarauðkenni:

- A18949116

- Uppfærsla:

- síðast þann 29.12.2025

Lýsing

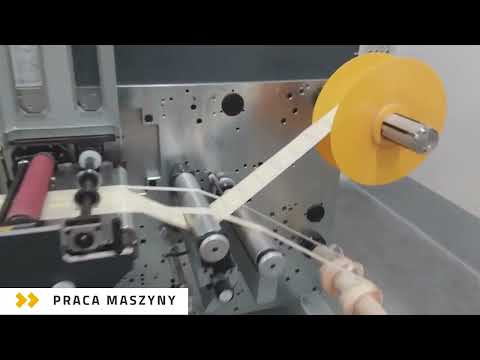

Segment I – Unwinder with stabilizing table

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Cjdpjwck U Rsfx Aflepw

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Þessi auglýsing var sjálfvirkt þýdd. Villa í þýðingu gæti verið til staðar.

The first segment is responsible for stable guidance of the material web. It is equipped with pins enabling both lamination and delamination of the face with liner or other raw material. It has a laminator with the possibility of precise pressure adjustment.

In addition:

• The hanging mechanism in each segment allows for continuous operation, eliminating the need to stop the machine while the flat die is working.

• Leading (pulling) servomotors ensure precise control of the material, also located in the station.

Cjdpjwck U Rsfx Aflepw

Segment II – Central (Die)

The heart of the machine is the flat die, allowing for cutting and embossing.

It has been equipped with:

• Hot stamping system – thanks to the heated plate with a mounted matrix, it allows for the application of effective decorations.

• Upper foil unwinders enabling additional material processing.

• Manual pressure adjustment – four independent clocks provide full control over the process, which is particularly important for irregular matrices and unconventional work.

• Lower trolley as an alternative to the hanging system – used depending on the specifics of the work.

Segment III – Puncher

The third segment is responsible for separating cut labels and transporting them to the receiving tray.

• Puncher – precise separation of single labels.

• Two laminators – one on each side of the puncher, with adjustable pressure.

• Unwinders and winders ensuring smooth guidance of additional raw material.

Segment IV – Rewinder

The last segment is responsible for the final winding of the finished material.

Equipped with:

• Two mandrels – enabling simultaneous or alternate winding of the finished product.

• Web tensioning system (nip holding and web tensioning) – ensuring stable guidance of the material.

• Slitting disc knife station.

• Whisk (waste) extraction system.

• Web sensors placed under each overhang, ensuring optimal process control.

Additional functionalities

• Remote control – the machine can be operated via the tablet included in the set.

• Mark sensor system (register) – precisely matches previously printed raw material, ensuring high accuracy and repeatability of production.

Þessi auglýsing var sjálfvirkt þýdd. Villa í þýðingu gæti verið til staðar.

Bjóðandi

Athugasemd: Skráðu þig ókeypis eða skráðu þig inn, til að fá aðgang að öllum upplýsingum.

Skráð frá: 2020

Senda fyrirspurn

Sími & Fax

+48 52 37... auglýsingar

Þessar auglýsingar gætu einnig vakið áhuga þinn.

Lítil auglýsing

Leinfelden-Echterdingen

Leinfelden-Echterdingen

2.455 km

FGT grafískar vélar - Breyting

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

Lítil auglýsing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

2.143 km

Stafræn prentvél

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

Lítil auglýsing

Bad Kreuznach

Bad Kreuznach

2.296 km

Flexographic prentvél

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

Lítil auglýsing

München

München

2.603 km

PITNEY BOWES DI425

Pitney BowesDI425

Pitney BowesDI425

Lítil auglýsing

Leinfelden-Echterdingen

Leinfelden-Echterdingen

2.455 km

FGT grafískar vélar - Breyting

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

Lítil auglýsing

Kaunas

Kaunas

2.580 km

Rewer

Jurmet

Jurmet

Lítil auglýsing

파주시

파주시

8.225 km

Fullkominn bandvél (Perfect Binder)

HorizonBQ-270

HorizonBQ-270

Lítil auglýsing

Þýskaland

Þýskaland

2.280 km

Labeling machine

GMLA 330

GMLA 330

Lítil auglýsing

Bischofszell

Bischofszell

2.572 km

SKOÐUNARSPEL

R.P.E.LRKP 350 MIT SCHNEIDEEINRICHTUNG

R.P.E.LRKP 350 MIT SCHNEIDEEINRICHTUNG

Lítil auglýsing

Leinfelden-Echterdingen

Leinfelden-Echterdingen

2.455 km

FGT grafískar vélar - Label Finisher

ROTOFLEXR 1300

ROTOFLEXR 1300

Auglýsingunni þinni hefur verið eytt með góðum árangri

Villa kom upp