Vökvakerfi pressaHidrobrasil

400 Tonnen Viersäulenpresse

Vökvakerfi pressa

Hidrobrasil

400 Tonnen Viersäulenpresse

Framleiðsluár

2020

Ástand

sýningavél

Staðsetning

Gelsenkirchen

Myndir sýna

Sýna kort

Upplýsingar um vélina

- Heiti vélar:

- Vökvakerfi pressa

- Framleiðandi:

- Hidrobrasil

- Framleiðsluár:

- 2020

- Ástand:

- næstum eins og ný (sýningavél)

Verð og staðsetning

- Staðsetning:

- Hertener Strasse 108, 45892 Gelsenkirchen, Deutschland

Hringdu

Tilboðsupplýsingar

- Auglýsingarauðkenni:

- A6102226

- Tilvísunarnúmer:

- HB 2021-A-114- 4

- Uppfærsla:

- síðast þann 27.03.2025

Lýsing

Hydraulic 400 to column press

suitable for continuous shift operation, with these basic data:

a) Closing speed 100 - 450 mm/sec.

b) Opening speed 50 - 250 mm/sec ( adjustable via touch screen )

c) Pressing speed 5 - 60 mm/sec ( adjustable via touch screen )

d) Piston accumulator with approx. 4 nitrogen bottles

e) Table size (clamping surface) 2700 x 1700mm ( seen from the front, between the columns )

f) Total table size 3400 x 1700mm

g) 28 T-slots according to customer requirements

h) Table, ram and press head are annealed stress-free.

i) column diameter 250 mm

j) slide size 3400 x 1700mm (clamping surface 2700 x 1700mm )

k) Total size of the machine approx. 3900 x 2200 ( at the bottom ) x 5700 mm height

l) Oil temperature monitoring ( adjustable via touch screen )

m) Automatic lubrication ( adjustable via touch screen )

n) Free positioning of the ram ( adjustable via touch screen )

o) KEYENCE light barriers 14 mm on front and rear side

p) Circuit oil cooling ( adjustable via touch screen )

q) Pressure holding valve 0 to 600 sec. ( adjustable via touch screen )

r) Table top size 3400 x 1700mm, plane milled

s) Laterally monitored doors, 1200mm high, 1000mm wide

t) RITTAL control cabinet, 2200 mm wide, up to 20 m from the press

u) Pressure setting from 50 to 400 tons ( adjustable via touch screen )

v) Travel limitation optionally via pressure or position

w) Programming mode, set-up mode, single stroke + continuous stroke (adjustable via rotary switch )

x) Swivelling control panel with 15 inch touch screen monitor

y) Two-hand operation on both sides

z) Prepared for automatic material feed ( SIEMENS S 7 1500 )

aa) Machine body primed and painted

bb) assembly, commissioning, instruction against separate charge

The hydraulics of the presses we offer are completely based on BOSCH-REXROTH/Parker/HAWE components. In the switch cabinet only components are used (SIEMENS) which are easily available in Germany. The safety technology comes completely from SICK except for the light barriers.

The control system is supplied by SIEMENS. ( S 7 1500 ) as well as the touch screen monitor with 15 inch. The SIEMENS remote maintenance unit SECOME -Ethernet is included in the scope of delivery.

SPECIAL FEATURE: the design chosen by us with two press cylinders and the piston accumulator make it possible to supply the full power with a main motor of 90 kW.

Below under 1.3 the technical details

Technical data

Press design

Press design Column press

Thermally neutral 80 - 120 °C

Number of operating sides 2 sides

Forces

Pressing force max. 4,000 kN

Free ripping force

max. 600 kN

Pressure build-up time Closed tool steel to steel Max. 2 sec.

Dimensions - intended minimum tool height 600 mm

Max. Opening width 1600 mm

Stroke and min. opening 1000/600 mm

Table height above floor 820 mm

Height above floor (headroom) approx. 5700 mm

Hall height min. 7000 mm

Parallel deviation

at 20°C +/- 0,1 mm

Deflection

Determined at max. clamping force with 70% occupancy

< = 0.17 mm/m

Bodpfx Afog Iihwolold

Weight

Total weight of the press without operating materials

approx. 52 To

Speeds ( see attached cycle diagram )

Fast closing 100 - 450

mm/s

Pressing speed At F max.

suitable for continuous shift operation, with these basic data:

a) Closing speed 100 - 450 mm/sec.

b) Opening speed 50 - 250 mm/sec ( adjustable via touch screen )

c) Pressing speed 5 - 60 mm/sec ( adjustable via touch screen )

d) Piston accumulator with approx. 4 nitrogen bottles

e) Table size (clamping surface) 2700 x 1700mm ( seen from the front, between the columns )

f) Total table size 3400 x 1700mm

g) 28 T-slots according to customer requirements

h) Table, ram and press head are annealed stress-free.

i) column diameter 250 mm

j) slide size 3400 x 1700mm (clamping surface 2700 x 1700mm )

k) Total size of the machine approx. 3900 x 2200 ( at the bottom ) x 5700 mm height

l) Oil temperature monitoring ( adjustable via touch screen )

m) Automatic lubrication ( adjustable via touch screen )

n) Free positioning of the ram ( adjustable via touch screen )

o) KEYENCE light barriers 14 mm on front and rear side

p) Circuit oil cooling ( adjustable via touch screen )

q) Pressure holding valve 0 to 600 sec. ( adjustable via touch screen )

r) Table top size 3400 x 1700mm, plane milled

s) Laterally monitored doors, 1200mm high, 1000mm wide

t) RITTAL control cabinet, 2200 mm wide, up to 20 m from the press

u) Pressure setting from 50 to 400 tons ( adjustable via touch screen )

v) Travel limitation optionally via pressure or position

w) Programming mode, set-up mode, single stroke + continuous stroke (adjustable via rotary switch )

x) Swivelling control panel with 15 inch touch screen monitor

y) Two-hand operation on both sides

z) Prepared for automatic material feed ( SIEMENS S 7 1500 )

aa) Machine body primed and painted

bb) assembly, commissioning, instruction against separate charge

The hydraulics of the presses we offer are completely based on BOSCH-REXROTH/Parker/HAWE components. In the switch cabinet only components are used (SIEMENS) which are easily available in Germany. The safety technology comes completely from SICK except for the light barriers.

The control system is supplied by SIEMENS. ( S 7 1500 ) as well as the touch screen monitor with 15 inch. The SIEMENS remote maintenance unit SECOME -Ethernet is included in the scope of delivery.

SPECIAL FEATURE: the design chosen by us with two press cylinders and the piston accumulator make it possible to supply the full power with a main motor of 90 kW.

Below under 1.3 the technical details

Technical data

Press design

Press design Column press

Thermally neutral 80 - 120 °C

Number of operating sides 2 sides

Forces

Pressing force max. 4,000 kN

Free ripping force

max. 600 kN

Pressure build-up time Closed tool steel to steel Max. 2 sec.

Dimensions - intended minimum tool height 600 mm

Max. Opening width 1600 mm

Stroke and min. opening 1000/600 mm

Table height above floor 820 mm

Height above floor (headroom) approx. 5700 mm

Hall height min. 7000 mm

Parallel deviation

at 20°C +/- 0,1 mm

Deflection

Determined at max. clamping force with 70% occupancy

< = 0.17 mm/m

Bodpfx Afog Iihwolold

Weight

Total weight of the press without operating materials

approx. 52 To

Speeds ( see attached cycle diagram )

Fast closing 100 - 450

mm/s

Pressing speed At F max.

Bjóðandi

Athugasemd: Skráðu þig ókeypis eða skráðu þig inn, til að fá aðgang að öllum upplýsingum.

Senda fyrirspurn

Sími & Fax

+49 209 9... auglýsingar

Þessar auglýsingar gætu einnig vakið áhuga þinn.

Lítil auglýsing

Gelsenkirchen

Gelsenkirchen

2.106 km

Vökvakerfi pressa

HidrobrasilDoppelständerpresse 400 Tonnen

HidrobrasilDoppelständerpresse 400 Tonnen

Lítil auglýsing

Þýskaland

Þýskaland

2.280 km

Vökvakerfi pressa

ISGEC300t - 2500t

ISGEC300t - 2500t

Lítil auglýsing

Birmingham

Birmingham

1.695 km

Vatnsþrýstingur

SchulerEB 2-500

SchulerEB 2-500

Lítil auglýsing

Wermelskirchen

Wermelskirchen

2.151 km

Vökvakerfi pressa

Hans SchoenUTE FF 300/80

Hans SchoenUTE FF 300/80

Lítil auglýsing

Korschenbroich

Korschenbroich

2.117 km

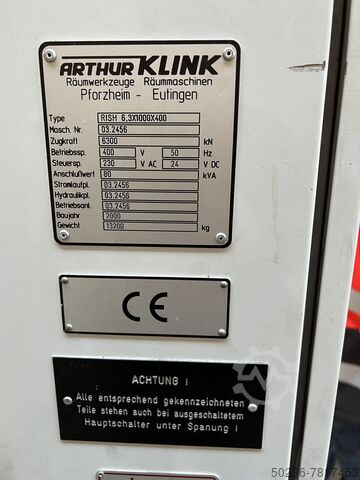

CNC innri broaching vél

Arthur KlinkRISH 6.3X1000X400

Arthur KlinkRISH 6.3X1000X400

Lítil auglýsing

Danmörk

Danmörk

1.811 km

NOTAÐ MAZAK CNC-RAFRÆNN RENNIBEKUR, GERÐ SQT 250 M-1000 L

MAZAKSQT 250 M-1000L

MAZAKSQT 250 M-1000L

Lítil auglýsing

Vaterstetten

Vaterstetten

2.610 km

Sprautumótunarvél

KraussMaffei Technologies GmbHKM 160 / 750 PA G01

KraussMaffei Technologies GmbHKM 160 / 750 PA G01

Lítil auglýsing

Metzingen

Metzingen

2.474 km

Þráður vals vél

PROFIROLL BAD DUEBENROLLEX

PROFIROLL BAD DUEBENROLLEX

Lítil auglýsing

Birmingham

Birmingham

1.695 km

Vökvakerfisteiknipressa

SMGHZPU

SMGHZPU

Lítil auglýsing

Ciriè

Ciriè

2.732 km

Tvöföld súlu vökvapressa

EMANUELDEA 400/2000

EMANUELDEA 400/2000

Auglýsingunni þinni hefur verið eytt með góðum árangri

Villa kom upp