FlokkunarmillHosokawa Alpine

ZPS 315

Flokkunarmill

Hosokawa Alpine

ZPS 315

framleiðsluár

1991

Ástand

Notað

Staðsetning

Augsburg

Myndir sýna

Sýna kort

Upplýsingar um vélina

- Heiti vélar:

- Flokkunarmill

- framleiðandi:

- Hosokawa Alpine

- Gerð:

- ZPS 315

- framleiðsluár:

- 1991

- Ástand:

- almennt endurnýjaður (notaður)

Verð og staðsetning

- Staðsetning:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

Hringdu

Vélasala

Fannstu nýja vél? Nú breytir þú því gamla í peninga.

Náðu bestu verði í gegnum Machineseeker.

Meira um sölu á vélum

Meira um sölu á vélum

Tilboðsupplýsingar

- Auglýsingarauðkenni:

- A9622523

- uppfærsla:

- síðast þann 10.02.2025

Lýsing

Used Hosokawa Alpine Zirkoplex ZPS 315 classifier mill

A HOSOKAWA ALPINE Originals machine

Dsdpfxelgy U Ne Aczowc

Refurbished by the original manufacturer

Use of original components only

Original manufacturer warranty

Guaranteed manufacturer spare parts supply

Short lead time

Before delivery, the machine is overhauled, all wear parts are revised and exchanged if needed and customized to your specific needs

Possibility to provide all additionally required peripherals or adapt to existing production plant

We are also interested in buying back disused HOSOKAWA ALPINE machinery

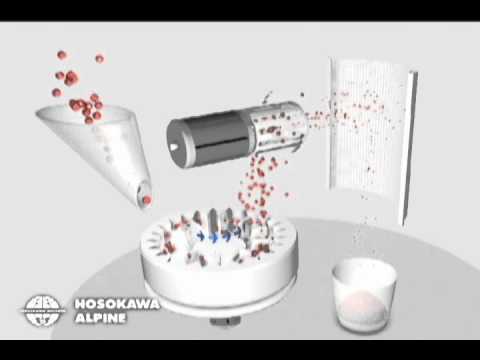

The Hosokawa Alpine Zirkoplex ZPS impact classifier mill is perfect for the fine grinding of different dry materials with a precise control over the particle´s top cut thanks to its integrated classifier wheel design, using the Alpine classifier ATP. It can be used to pulverize different products and within different industries where micronization might be needed, such as minerals, chemicals, food, pharma, etc. The comminution takes place in the bottom part of the grinding chamber where the rotor plate fitted with grinding tools (hammers or pins) impacts and projects the particles against the liner in order to break them. Within the same chamber, the air circulation brings the fines to the rotating classifier wheel where oversize grains are rejected to then return to the griding zone for reprocessing, whereas the fine particles make it through the classification step to the next stage, normally the filter. Thanks to the required process air volume, reduced temperature increase during grinding is to be expected compared to other granulation technologies. Adjusting the final particle size distribution can be easily done by changing different parameters, such as the speed of the grinding rotor or disc and the classifier wheel, air volume, feeding rate, etc.

Material of construction: mild steel

Without wear protection

Non Pressure Shock Resistant (NPSR), non-ATEX

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, a set of grinding tools of choice and installation table

A HOSOKAWA ALPINE Originals machine

Dsdpfxelgy U Ne Aczowc

Refurbished by the original manufacturer

Use of original components only

Original manufacturer warranty

Guaranteed manufacturer spare parts supply

Short lead time

Before delivery, the machine is overhauled, all wear parts are revised and exchanged if needed and customized to your specific needs

Possibility to provide all additionally required peripherals or adapt to existing production plant

We are also interested in buying back disused HOSOKAWA ALPINE machinery

The Hosokawa Alpine Zirkoplex ZPS impact classifier mill is perfect for the fine grinding of different dry materials with a precise control over the particle´s top cut thanks to its integrated classifier wheel design, using the Alpine classifier ATP. It can be used to pulverize different products and within different industries where micronization might be needed, such as minerals, chemicals, food, pharma, etc. The comminution takes place in the bottom part of the grinding chamber where the rotor plate fitted with grinding tools (hammers or pins) impacts and projects the particles against the liner in order to break them. Within the same chamber, the air circulation brings the fines to the rotating classifier wheel where oversize grains are rejected to then return to the griding zone for reprocessing, whereas the fine particles make it through the classification step to the next stage, normally the filter. Thanks to the required process air volume, reduced temperature increase during grinding is to be expected compared to other granulation technologies. Adjusting the final particle size distribution can be easily done by changing different parameters, such as the speed of the grinding rotor or disc and the classifier wheel, air volume, feeding rate, etc.

Material of construction: mild steel

Without wear protection

Non Pressure Shock Resistant (NPSR), non-ATEX

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, a set of grinding tools of choice and installation table

Bjóðandi

Athugasemd: Skráðu þig ókeypis eða skráðu þig inn, til að fá aðgang að öllum upplýsingum.

Skráð frá: 2019

Senda fyrirspurn

Sími & Fax

+49 821 2... auglýsingar

Þessar auglýsingar gætu einnig vakið áhuga þinn.

lítil auglýsing

Augsburg

Augsburg

2.555 km

Flokkunarmill

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

lítil auglýsing

Arnsberg

Arnsberg

2.154 km

Flokkunarmylla

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

Auglýsingunni þinni hefur verið eytt með góðum árangri

Villa kom upp