Þvottavél úr gleriKlöpper

2600 mm R-L

Þvottavél úr gleri

Klöpper

2600 mm R-L

Framleiðsluár

2021

Ástand

Notað

Staðsetning

Maasmechelen

Myndir sýna

Sýna kort

Upplýsingar um vélina

- Heiti vélar:

- Þvottavél úr gleri

- Framleiðandi:

- Klöpper

- Gerð:

- 2600 mm R-L

- Framleiðsluár:

- 2021

- Ástand:

- næstum eins og nýtt (notað)

- Virkni:

- fullkomlega virkur

Verð og staðsetning

- Staðsetning:

- Breitwaterstraat 22, 3630 Maasmechelen, Belgique

Hringdu

Tilboðsupplýsingar

- Auglýsingarauðkenni:

- A16330962

- Tilvísunarnúmer:

- S-WSH-504

- Uppfærsla:

- síðast þann 18.08.2025

Lýsing

Vertical infeed transport

- Vertical 2600 mm washing machine with drying

- Tilting table (behind the washing machine)

- Horizontal outfeed transport

Pos. 1 Loading station, 250kg

With the help of the suction frame, the sheets are taken off the glass rack and they are placed vertically on the tilting table in front of the washing machine. Differences in inclination can be compensated by tilting of the suction frame. The suction frame has a rotating function to collect short formats in upright position and to place them down on the long edge.

Light crane

Trolley crane with a lift system travelling on rails by hand, which are standing on steel supports.

Lift

Electrical lifting and lowering, horizontal turning and tilting of loads.

Generation of vacuum via vacuum pump system with check and display of the vacuum power.

A central operation desk with integrated control buttons allows easy signal activation of the single functions. In case of pressure loss in the dangerous area, it is displayed and acoustical signal is given.

Pos. 2 Vertical Inlet Transport WM

The vertical transport serves as inlet transport in front of the washing machine.

In horizontal position, the glass sheets are placed on Vulcan transport rollers.

In vertical position transport rollers with Perumaan rings are driven via screw wheels. The transport rollers are arranged in drag bearings placed on a solid welded frame.

Small glass sheets are placed manually on the transport frame. After placing the glass sheet, the transport is activated by push button.

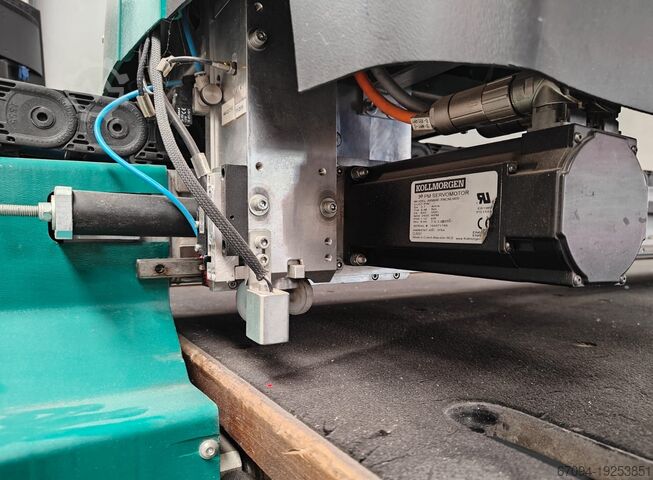

Pos. 3 Vertical Washing Machine with Drying

The washing machine body, washing chambers, recirculation vats and the drying nozzles are made entirely of stainless steel.

The rubber rings of the transport rollers are resistant to cutting oil.

Flat jet spraying nozzles in the pre-rinsing section are fed with city water. Coarse dirt particles removed are directly led into the drain. This reduces contamination of the DI-water circuit for the washing machine.

The washing machine is equipped with energy and water saving cascade system.

Pre-rinsing section with

Flat jet spraying nozzles

Washing section with

3 pairs of brushes,

3 vats and

3 pumps

Acid section with

Psdpfxotwphwo Agmjgg

1 pair of brushes,

1 vat and

1 pump

Drying section with

2 pairs of drying nozzles provide dry edges.

Pos. 4 Vertical Inspection Transport with glass Activation Section

The transport serves as Activation Section for the glass surface and as Inspection and Storage Transport before the Tilting Table.

Drive by a geared motor, A.C., frequency controlled. All the rollers are arranged in drag bearings with a single drive operating pairs of spiral-toothed gear wheels.

The transport rollers are vulcanized and ground.

Pos. 5 Tilting Table with Horizontal Transport and Vertical Inspection

- Vertical 2600 mm washing machine with drying

- Tilting table (behind the washing machine)

- Horizontal outfeed transport

Pos. 1 Loading station, 250kg

With the help of the suction frame, the sheets are taken off the glass rack and they are placed vertically on the tilting table in front of the washing machine. Differences in inclination can be compensated by tilting of the suction frame. The suction frame has a rotating function to collect short formats in upright position and to place them down on the long edge.

Light crane

Trolley crane with a lift system travelling on rails by hand, which are standing on steel supports.

Lift

Electrical lifting and lowering, horizontal turning and tilting of loads.

Generation of vacuum via vacuum pump system with check and display of the vacuum power.

A central operation desk with integrated control buttons allows easy signal activation of the single functions. In case of pressure loss in the dangerous area, it is displayed and acoustical signal is given.

Pos. 2 Vertical Inlet Transport WM

The vertical transport serves as inlet transport in front of the washing machine.

In horizontal position, the glass sheets are placed on Vulcan transport rollers.

In vertical position transport rollers with Perumaan rings are driven via screw wheels. The transport rollers are arranged in drag bearings placed on a solid welded frame.

Small glass sheets are placed manually on the transport frame. After placing the glass sheet, the transport is activated by push button.

Pos. 3 Vertical Washing Machine with Drying

The washing machine body, washing chambers, recirculation vats and the drying nozzles are made entirely of stainless steel.

The rubber rings of the transport rollers are resistant to cutting oil.

Flat jet spraying nozzles in the pre-rinsing section are fed with city water. Coarse dirt particles removed are directly led into the drain. This reduces contamination of the DI-water circuit for the washing machine.

The washing machine is equipped with energy and water saving cascade system.

Pre-rinsing section with

Flat jet spraying nozzles

Washing section with

3 pairs of brushes,

3 vats and

3 pumps

Acid section with

Psdpfxotwphwo Agmjgg

1 pair of brushes,

1 vat and

1 pump

Drying section with

2 pairs of drying nozzles provide dry edges.

Pos. 4 Vertical Inspection Transport with glass Activation Section

The transport serves as Activation Section for the glass surface and as Inspection and Storage Transport before the Tilting Table.

Drive by a geared motor, A.C., frequency controlled. All the rollers are arranged in drag bearings with a single drive operating pairs of spiral-toothed gear wheels.

The transport rollers are vulcanized and ground.

Pos. 5 Tilting Table with Horizontal Transport and Vertical Inspection

Bjóðandi

Athugasemd: Skráðu þig ókeypis eða skráðu þig inn, til að fá aðgang að öllum upplýsingum.

Skráð frá: 2019

Senda fyrirspurn

Sími & Fax

+32 89 53... auglýsingar

Þessar auglýsingar gætu einnig vakið áhuga þinn.

Lítil auglýsing

Gondelsheim

Gondelsheim

2.401 km

Loftkrani innanhúss krana krana flugbraut krana

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Lítil auglýsing

Szczecin

Szczecin

2.264 km

þétt geymsla fyrir gler

HEGLAKPL-MZ-III, 36

HEGLAKPL-MZ-III, 36

Lítil auglýsing

Essen

Essen

2.108 km

Einbreiður hálfgerður kranar

Teichmann Krane

Teichmann Krane

Lítil auglýsing

Velen

Velen

2.072 km

Kaldur hringhringur

BERG & SCHMIDRecord 315/350 S

BERG & SCHMIDRecord 315/350 S

Lítil auglýsing

Gościcino

Gościcino

2.332 km

Skurðarborð úr gleri

GlastonUC 1000

GlastonUC 1000

Lítil auglýsing

Zamość

Zamość

2.882 km

Afrita fræsivél

RotoxZOR 941

RotoxZOR 941

Lítil auglýsing

Brendola

Brendola

2.850 km

Vörubíll með föstum palli

Iveco

Iveco

Lítil auglýsing

Maasmechelen

Maasmechelen

2.105 km

Glerskurðarborð

Bottero353BKM-J

Bottero353BKM-J

Lítil auglýsing

Barbing

Barbing

2.550 km

Glerborvél tvíhliða

Schiatti AngeloFPD60

Schiatti AngeloFPD60

Lítil auglýsing

Zielona Góra

Zielona Góra

2.435 km

Trésmíðavél

BOOSTONER-02

BOOSTONER-02

Auglýsingunni þinni hefur verið eytt með góðum árangri

Villa kom upp