Cnc rennibekkurMuratec

MT200

Cnc rennibekkur

Muratec

MT200

EXW föst verð aukaskattur bætist við

85.711 EUR

Framleiðsluár

2015

Ástand

Notað

Staðsetning

Iași

Myndir sýna

Sýna kort

Upplýsingar um vélina

- Heiti vélar:

- Cnc rennibekkur

- Framleiðandi:

- Muratec

- Gerð:

- MT200

- Vélar númer:

- 15KX239200001

- Framleiðsluár:

- 2015

- Ástand:

- gott (notað)

- Virkni:

- fullkomlega virkur

Verð og staðsetning

EXW föst verð aukaskattur bætist við

85.711 EUR

- Staðsetning:

- Calea Chisinaului Nr. 132, C4 building, C1-parter, 1 floor, C2-parter, et.1, 700178 Iași, România

Hringdu

Tilboðsupplýsingar

- Auglýsingarauðkenni:

- A20529360

- Tilvísunarnúmer:

- T05

- Uppfærsla:

- síðast þann 30.12.2025

Lýsing

Technical specifications:

Work Area

- Maximum turning diameter: 210 mm

- Maximum machining diameter: 200 mm

- Maximum workpiece length: 220 mm

- X1/X2 axis travel: 220 mm / Rapid traverse in X: 24 m/min

- Z1/Z2 axis travel: 220/770 mm / Rapid traverse in Z: 36 m/min

- Y1/Y2 axis travel: +/-40 mm / Rapid traverse in Y: 12 m/min

Automation:

- Axis strokes: X - 210 mm; Y - 680 mm; Z - Left 2080 mm / Right 3360 mm; α 270˚

- Maximum speeds (m/min): X - 35; Y - 120; Z - 160; α 270˚/1.5 sec

- Load/unload gripper specifications (pneumatically powered): Outer diameter up to Ø170 mm; jaw stroke 30 mm; gripping force: external 128 kgf / internal 138 kgf

Main Spindle:

- Spindle nose: A8

- Maximum speed: Left 5000 rpm / Right 5000 rpm

- Power at 100% duty cycle: Left - 15 kW / Right - 7.5 kW

- Bar capacity: left spindle - 65 mm / right spindle - not available

Tool Turret with Driven Tools:

Ihodpfx Ajxwuhusf Rot

- Tool interface: BMT55

- Number of positions: 15 upper / 12 lower station turret, all driven positions

- Maximum speed: 4500 rpm; Milling motor power: 4.5 kW

Electrical Equipment:

- Operating voltage: 200V, 3-phase, 151A fuse

- Connected load: 55 kVA

Dimensions:

- Machine dimensions (L×W×H): 3200 × 2200 × 3500 mm

- Weight: 10,500 kg

Main Features and Capabilities:

- Horizontal design: Optimal chip removal, gantry loading/unloading from conveyors

- Automation includes: Gantry robot + 2 loading/unloading conveyors

- CNC control: Fanuc FS31i Model A Series

- Chip removal conveyor

- Coolant filtration 40 bar max: Filber S.L. FTH5/10, 200 l/min

- In-process control: Marposs T25

- Broken tool detection system: Peek tool menu Murata/Fanuc feature enabled

- Part detection through spindle: Low pressure compressed air sensors

- Bar feeder interface max Ø65 mm

- Documentation: Electronic and hard copy available

Machine condition:

OPERATIONAL

Þessi auglýsing var sjálfvirkt þýdd. Villa í þýðingu gæti verið til staðar.

Work Area

- Maximum turning diameter: 210 mm

- Maximum machining diameter: 200 mm

- Maximum workpiece length: 220 mm

- X1/X2 axis travel: 220 mm / Rapid traverse in X: 24 m/min

- Z1/Z2 axis travel: 220/770 mm / Rapid traverse in Z: 36 m/min

- Y1/Y2 axis travel: +/-40 mm / Rapid traverse in Y: 12 m/min

Automation:

- Axis strokes: X - 210 mm; Y - 680 mm; Z - Left 2080 mm / Right 3360 mm; α 270˚

- Maximum speeds (m/min): X - 35; Y - 120; Z - 160; α 270˚/1.5 sec

- Load/unload gripper specifications (pneumatically powered): Outer diameter up to Ø170 mm; jaw stroke 30 mm; gripping force: external 128 kgf / internal 138 kgf

Main Spindle:

- Spindle nose: A8

- Maximum speed: Left 5000 rpm / Right 5000 rpm

- Power at 100% duty cycle: Left - 15 kW / Right - 7.5 kW

- Bar capacity: left spindle - 65 mm / right spindle - not available

Tool Turret with Driven Tools:

Ihodpfx Ajxwuhusf Rot

- Tool interface: BMT55

- Number of positions: 15 upper / 12 lower station turret, all driven positions

- Maximum speed: 4500 rpm; Milling motor power: 4.5 kW

Electrical Equipment:

- Operating voltage: 200V, 3-phase, 151A fuse

- Connected load: 55 kVA

Dimensions:

- Machine dimensions (L×W×H): 3200 × 2200 × 3500 mm

- Weight: 10,500 kg

Main Features and Capabilities:

- Horizontal design: Optimal chip removal, gantry loading/unloading from conveyors

- Automation includes: Gantry robot + 2 loading/unloading conveyors

- CNC control: Fanuc FS31i Model A Series

- Chip removal conveyor

- Coolant filtration 40 bar max: Filber S.L. FTH5/10, 200 l/min

- In-process control: Marposs T25

- Broken tool detection system: Peek tool menu Murata/Fanuc feature enabled

- Part detection through spindle: Low pressure compressed air sensors

- Bar feeder interface max Ø65 mm

- Documentation: Electronic and hard copy available

Machine condition:

OPERATIONAL

Þessi auglýsing var sjálfvirkt þýdd. Villa í þýðingu gæti verið til staðar.

Bjóðandi

Athugasemd: Skráðu þig ókeypis eða skráðu þig inn, til að fá aðgang að öllum upplýsingum.

Skráð frá: 2025

Senda fyrirspurn

Sími & Fax

+40 742 1... auglýsingar

Þessar auglýsingar gætu einnig vakið áhuga þinn.

Lítil auglýsing

Podbočje

Podbočje

2.975 km

CNC rennibekkur

TraubTNA400

TraubTNA400

Lítil auglýsing

Idstein

Idstein

2.276 km

CNC rennibekkur

MuratecMT 100 T3 Y3

MuratecMT 100 T3 Y3

Lítil auglýsing

Hövelhof

Hövelhof

2.149 km

Lóðréttur broaching vél 16to

Arthur Klink

Arthur Klink

Lítil auglýsing

Székesfehérvár

Székesfehérvár

2.977 km

Muratec MW 120

MuratecMuratec MW120 GT

MuratecMuratec MW120 GT

Lítil auglýsing

Hövelhof

Hövelhof

2.149 km

Innri snertavél

Arthur KlinkRISZ 10x1000x400

Arthur KlinkRISZ 10x1000x400

Lítil auglýsing

Fuente de Cantos

Fuente de Cantos

3.088 km

SPLINE ROLLING

EX CELL OROTO FLO 3225

EX CELL OROTO FLO 3225

Lítil auglýsing

Korschenbroich

Korschenbroich

2.117 km

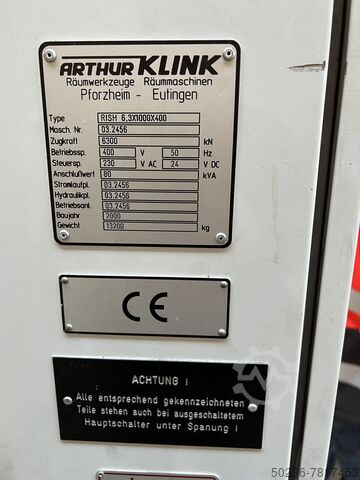

CNC innri broaching vél

Arthur KlinkRISH 6.3X1000X400

Arthur KlinkRISH 6.3X1000X400

Lítil auglýsing

Neulingen-Göbrichen

Neulingen-Göbrichen

2.412 km

Broaching Machine lóðrétt

EKINRISZ 10/1000

EKINRISZ 10/1000

Lítil auglýsing

Þýskaland

Þýskaland

2.412 km

Rennibekkur - hringrásastýrður

KERN-DMTCD 480

KERN-DMTCD 480

Lítil auglýsing

Malsch

Malsch

2.404 km

CNC rennibekkur

TRAUBTNA 300

TRAUBTNA 300

Auglýsingunni þinni hefur verið eytt með góðum árangri

Villa kom upp