Vatn, olía, sápa, AdBlue áfyllingarvélPROTON EE-ELEKTRONIKA d.o.o

XFR1000

Vatn, olía, sápa, AdBlue áfyllingarvél

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

Framleiðsluár

2025

Ástand

Nýtt

Staðsetning

Šašinovec

Myndir sýna

Sýna kort

Upplýsingar um vélina

- Heiti vélar:

- Vatn, olía, sápa, AdBlue áfyllingarvél

- Framleiðandi:

- PROTON EE-ELEKTRONIKA d.o.o

- Gerð:

- XFR1000

- Framleiðsluár:

- 2025

- Ástand:

- nýtt

- Virkni:

- fullkomlega virkur

Verð og staðsetning

- Staðsetning:

- Krcevina 4, 10360 Soblinec, Hrvatska

Hringdu

Tæknilegar upplýsingar

- Heildarbreidd:

- 2.400 mm

- Heildarlengd:

- 15.000 mm

- Heildarhæð:

- 2.800 mm

- Þrýstingur:

- 8 stöng

- Afl:

- 10,9 kW (14,82 hP)

- Tómass:

- 6.400 kg

- Inngangsspenna:

- 400 V

- Fyllingarþyngd (lágmark):

- 200 g

- Fyllingarþyngd (mest):

- 5.000 g

Tilboðsupplýsingar

- Auglýsingarauðkenni:

- A17231422

- Uppfærsla:

- síðast þann 25.09.2025

Lýsing

XFR 1000

Liquid Media Filling Line

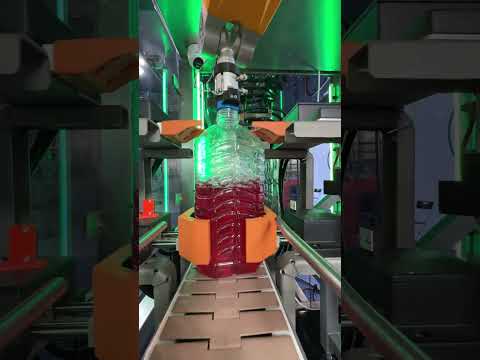

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

Codpsuq Nv Tefx Abbjgn

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

Codpsuq Nv Tefx Abbjgn

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Bjóðandi

Athugasemd: Skráðu þig ókeypis eða skráðu þig inn, til að fá aðgang að öllum upplýsingum.

Skráð frá: 2020

Senda fyrirspurn

Sími & Fax

+385 43 3... auglýsingar

Þessar auglýsingar gætu einnig vakið áhuga þinn.

Lítil auglýsing

Kirchheimbolanden

Kirchheimbolanden

2.318 km

Merkingarkerfi fyrir kringlóttar og ferhyrndar dósir

Weidmann Maschinen EtikettiermaschineFL-800

Weidmann Maschinen EtikettiermaschineFL-800

Lítil auglýsing

Δράμα

Δράμα

3.790 km

Offsetprentunartegund

ShinoharaSHINOHARA 75

ShinoharaSHINOHARA 75

Lítil auglýsing

Rīga

Rīga

2.440 km

Sjálfvirkur hvítkálkjarna bor KU-2400

Alistar EuropeKU-2400

Alistar EuropeKU-2400

Lítil auglýsing

London

London

1.848 km

Drykkjarframleiðsluvél

GEACRAFT STAR 40/50HL BREWHOUSE

GEACRAFT STAR 40/50HL BREWHOUSE

Lítil auglýsing

Tata

Tata

2.931 km

Excentrísk pressa AIDA NC2-250, 250 tonn

AIDA NC1-250250ton

AIDA NC1-250250ton

Lítil auglýsing

Kreuzau

Kreuzau

2.158 km

Vinnsluaðstaða

FrymaMZM / VK 50

FrymaMZM / VK 50

Lítil auglýsing

Niedźwiedź

Niedźwiedź

2.834 km

Þjöppu eining eimsvala eining

BITZERHSK7461-80-40P

BITZERHSK7461-80-40P

Lítil auglýsing

Raszyn

Raszyn

2.656 km

Pípubúnaður, pípubúningsvél

Jedlinski PackagingJTB-40

Jedlinski PackagingJTB-40

Lítil auglýsing

Schorfheide

Schorfheide

2.272 km

Kyrrstæð blöndunarstöð

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Sonstige/OtherFrumecar Fastmix DIE BETONTANKSTELLE

Lítil auglýsing

Fumane (Verona)

Fumane (Verona)

2.823 km

Sírópsherbergi

ALFA LAVAL

ALFA LAVAL

Auglýsingunni þinni hefur verið eytt með góðum árangri

Villa kom upp