KERFI FYRIR STAFRÆNA BÓKAFRAMLEIÐSLUTECNAU

LIBRA 800

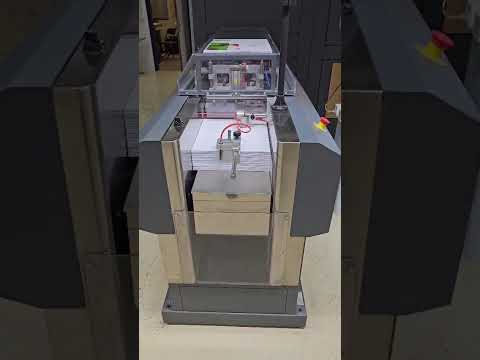

KERFI FYRIR STAFRÆNA BÓKAFRAMLEIÐSLU

TECNAU

LIBRA 800

Framleiðsluár

2017

Ástand

Notað

Staðsetning

Europa

Myndir sýna

Sýna kort

Upplýsingar um vélina

- Heiti vélar:

- KERFI FYRIR STAFRÆNA BÓKAFRAMLEIÐSLU

- Framleiðandi:

- TECNAU

- Gerð:

- LIBRA 800

- Framleiðsluár:

- 2017

- Ástand:

- mjög gott (notað)

Verð og staðsetning

- Staðsetning:

- Europa

Hringdu

Tilboðsupplýsingar

- Auglýsingarauðkenni:

- A21287107

- Tilvísunarnúmer:

- 40001.26

- Uppfærsla:

- síðast þann 20.02.2026

Lýsing

HIGHLY AUTOMATED, MODULAR SYSTEM FOR DIGITAL BOOK PRODUCTION ("BOOK ON DEMAND") AND SHORT RUNS – TECNAU LIBRA 800

Intended Use: Suitable for the conversion and processing of short runs and single copies ("books of one") with variable sizes, page counts, and covers.

Performance: from print run 1; up to 800 copies per hour

Book Format: min. 100 x 125 mm / max. A4

Thickness: min. 2 mm / max. 60 mm

Equipment / Further Details:

Line Configuration:

1.Roll-to-Stack Feed: Unwinder, merger, Dupla cutter, and book assembly station for the production of book blocks with 2-up printing.

2.Sheet Feeder: A variable number of loose sheets can be added as inserts to the book block. The sheets must have the same size and print run as the book block being processed.

3.Infeed to Binder: Manual feeding station for pre-fabricated book blocks, conveyor with scanning station, book turnover module, and robotic loader at the binder.

4.Variable Binder: For the production of softcover books. The binder is equipped with PUR for the spine and hot-melt glue for the side gluing.

5.Softcover Cover Feeder: Configured with a sheet cover feeder; pre-printed covers are fed, trimmed at the front, side-trimmed, and creased to the exact thickness of the corresponding book block.

6.Cooling Tower: Books are transported from the binder through the cooling tower to the three-knife trimmer.

7.Variable Three-Knife Trimmer: Suitable for trimming books with variable dimensions in three axes and different cover types.

8.System Control Software

Finishing Line

The entire process is controlled via 2D Data Matrix codes. Through the code, the system receives authorization for the following automatic settings and workflow control:

• Information on book dimensions and inserts (quantity and sequence)

• Binder setup (spine position, thickness, and length)

• Cover preparation: Softcover → creasing, cutting, edge trimming

• Correct book-to-cover matching

• Three-knife trimmer (blade positioning is automatically adjusted to the book dimensions)

Kljdpfxsylyhde Ad Don

Intended Use: Suitable for the conversion and processing of short runs and single copies ("books of one") with variable sizes, page counts, and covers.

Performance: from print run 1; up to 800 copies per hour

Book Format: min. 100 x 125 mm / max. A4

Thickness: min. 2 mm / max. 60 mm

Equipment / Further Details:

Line Configuration:

1.Roll-to-Stack Feed: Unwinder, merger, Dupla cutter, and book assembly station for the production of book blocks with 2-up printing.

2.Sheet Feeder: A variable number of loose sheets can be added as inserts to the book block. The sheets must have the same size and print run as the book block being processed.

3.Infeed to Binder: Manual feeding station for pre-fabricated book blocks, conveyor with scanning station, book turnover module, and robotic loader at the binder.

4.Variable Binder: For the production of softcover books. The binder is equipped with PUR for the spine and hot-melt glue for the side gluing.

5.Softcover Cover Feeder: Configured with a sheet cover feeder; pre-printed covers are fed, trimmed at the front, side-trimmed, and creased to the exact thickness of the corresponding book block.

6.Cooling Tower: Books are transported from the binder through the cooling tower to the three-knife trimmer.

7.Variable Three-Knife Trimmer: Suitable for trimming books with variable dimensions in three axes and different cover types.

8.System Control Software

Finishing Line

The entire process is controlled via 2D Data Matrix codes. Through the code, the system receives authorization for the following automatic settings and workflow control:

• Information on book dimensions and inserts (quantity and sequence)

• Binder setup (spine position, thickness, and length)

• Cover preparation: Softcover → creasing, cutting, edge trimming

• Correct book-to-cover matching

• Three-knife trimmer (blade positioning is automatically adjusted to the book dimensions)

Kljdpfxsylyhde Ad Don

Bjóðandi

Athugasemd: Skráðu þig ókeypis eða skráðu þig inn, til að fá aðgang að öllum upplýsingum.

Senda fyrirspurn

Sími & Fax

+41 71 54... auglýsingar

Auglýsingunni þinni hefur verið eytt með góðum árangri

Villa kom upp